The aluminum stamping process deep drawn stamping is a viable forming method when surface abrasion is a concern and is mainly employed for larger production runs and long term applications.

09 aluminum sheet deep drawn.

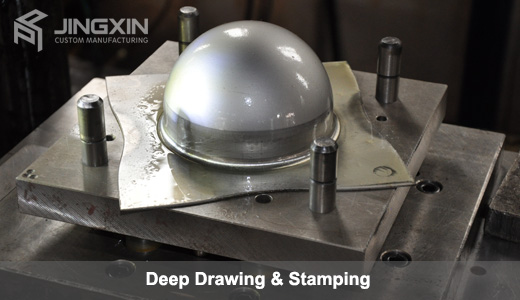

This form of metal stamping involves applying a punching force to a metal sheet thereby causing it to be drawn radially into a die cavity.

Stamping is a general term that encompasses a broad range of metal forming capabilities and industrial uses.

Experimentally several laboratory methods are utilized to assess the ductility of the sheets.

Imagine now a sheet metal blank being deep drawn into a round cylindrical part.

Aluminum stamping uses mechanical presses and dies to form sheet metal into parts.

Our services contract manufacturing.

This article covers only a couple of factors.

Deep drawing is the most important process of shaping sheet where largely deformed metal sheets are turned into the hollow parts.

Sometimes in deep drawing an amount of sheet metal material is not drawn into the die and forms a flange around the completed part.

What is deep drawn metal stamping.

The material under the punch gets forced into the cavity pulling material with it to form the walls of the part.

As a leading company in metal stamping services wedge products has the versatility to utilize various processes to create high quality components for countless applications.

Deep drawn stamping deep draw metal stamping our state of the art facility houses 50 metal stamping presses from 3 to 400 ton.

In general a metal forming process is called deep drawing if the depth of the drawn part exceeds its diameter.

Services include metal stamping hydroforming deep drawing plating laser welding heat treating cnc machining aluminum extrusion die casting.

Our capabilities include prototyping engineering part design development 3d modeling.

We produce quality cnc machined parts sheet metal fabrication metal stamping parts contract manufacturering wire forming parts deep drawn enclosures and related metal parts.

Parts produced by metal stamping can range from 0 25 inches in diameter or smaller to very large aircraft automotive and appliance parts.

It doesn t matter if you making an automobile hood or a deep drawn cup.

These test methods include cylindrical cup deep drawing and deep shaping operations.

Many controlling factors contribute to the success of an aluminum stamping and many of those factors are controlled to a great degree by the mechanical properties of the aluminum sheet.